Owning a truck opens the door to a world of possibilities, from off-road adventures to daily hauling tasks. However, to maximize the utility and comfort of your new vehicle, investing in the right accessories is essential. These accessories not only enhance the functionality of your truck but also improve your driving experience.

In this article, we will explore the top ten accessories that every new truck owner should consider. From storage solutions to protective gear, finding the perfect items can make a significant difference in how you use and enjoy your truck. Whether you’re a weekend warrior tackling the great outdoors or a daily commuter navigating city streets, the right accessories can elevate your truck ownership experience.

Understanding your specific needs and the types of activities you plan to engage in will help you choose accessories that are both practical and essential. Let’s delve into the must-have accessories that will not only protect your investment but also enhance your adventures on the road.

Must-Have Tools for Truck Maintenance and Repair

As a new truck owner, investing in the right tools for maintenance and repair is essential to keep your vehicle in top condition. Here are essential tools that every truck owner should have:

1. Socket Set

A comprehensive socket set is a must-have, featuring both metric and SAE sizes. It allows you to tackle a wide range of tasks, from changing oil to replacing parts. Look for a set with a ratchet and extensions for hard-to-reach areas.

2. Wrench Set

A good set of wrenches, including adjustable and combination wrenches, enables efficient loosening and tightening of bolts and nuts. Consider both standard and metric sizes for versatility.

3. Pliers

Quality pliers, including needle-nose and locking pliers, are crucial for gripping, twisting, and cutting wires and hoses. They can be indispensable during electrical repairs or when accessing tight spots.

4. Screwdriver Set

A set of screwdrivers with various types and sizes is vital for dealing with countless screws and fasteners in your truck. Ensure to include both flathead and Phillips screwdrivers for maximum utility.

5. Tire Pressure Gauge

Maintaining proper tire pressure is crucial for safety and fuel efficiency. A reliable tire pressure gauge allows you to monitor your tires regularly, helping to prevent blowouts and uneven wear.

6. Jack and Jack Stands

A quality hydraulic jack, along with sturdy jack stands, is essential for safely lifting your truck during repairs or tire changes. Make sure the jack can handle the weight of your vehicle.

7. Oil Filter Wrench

This tool simplifies the process of removing and installing oil filters, making oil changes easier and more efficient. A simple twist can save you time and frustration during routine maintenance.

8. Multimeter

A multimeter is invaluable for diagnosing electrical issues, allowing you to measure voltage, current, and resistance in various components. This tool is essential for troubleshooting problems effectively.

9. Torque Wrench

A torque wrench ensures that bolts are tightened to the manufacturer’s specifications. This is critical for components like the wheel lug nuts, preventing damage and ensuring safety on the road.

10. Creeper

A creeper provides comfort and ease when working under your truck, allowing you to slide effortlessly while performing maintenance tasks. It saves your back and makes access much easier.

Equipping yourself with these must-have tools will not only make truck maintenance more manageable but also save you time and money in the long run.

Essential Safety Gear to Keep in Your Truck

Ensuring safety on the road is paramount for every truck owner. Having the right safety gear in your truck can make a significant difference in emergency situations. Here are some essential items you should always keep in your vehicle:

1. First Aid Kit: A comprehensive first aid kit is crucial for addressing injuries that may occur on the road. Make sure it includes bandages, antiseptic wipes, gauze, scissors, and any necessary medications. Regularly check the kit to replace expired items.

2. Fire Extinguisher: A portable fire extinguisher is vital for preventing small fires from escalating. Look for a Class B or Class C extinguisher, suitable for flammable liquids and electrical fires. Ensure it’s easily accessible in your truck.

3. Reflective Triangles or Flares: In case of a breakdown, use reflective triangles or flares to alert other drivers. This increases visibility, especially at night, and helps prevent accidents while you manage the situation.

4. Jumper Cables: Dead batteries are a common occurrence. Keeping a pair of high-quality jumper cables can save you from being stranded. Be sure to know how to use them properly or read the instructions if you’re unfamiliar.

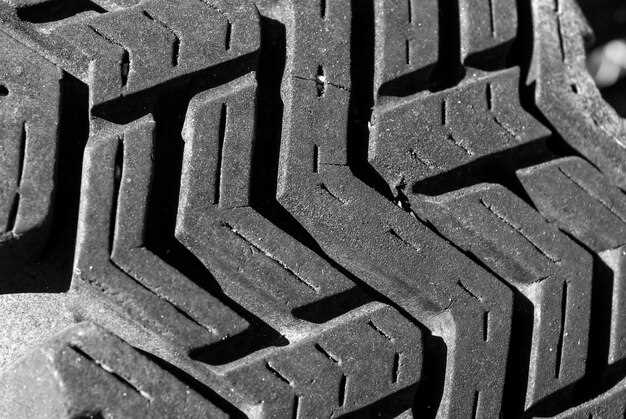

5. Tire Repair Kit: A flat tire can halt your journey. Carry a tire repair kit that includes a tire inflator and sealant. Familiarize yourself with the kit to efficiently handle tire issues when they arise.

6. Emergency Blankets: An emergency blanket can provide warmth in case of unexpected weather changes or emergencies. These lightweight, compact blankets are easy to store and can be a lifesaver during cold nights.

7. Multi-Tool: A multi-tool is versatile for various emergency needs. It can include pliers, a knife, screwdrivers, and other functions that may come in handy during repairs or emergencies.

8. Flashlight: A reliable flashlight is essential for low-light situations. Choose a durable, high-lumen flashlight, and consider keeping extra batteries or a rechargeable option in your truck.

9. Tow Straps: Tow straps are useful if you need to pull a friend or yourself out of a tricky situation. Ensure the straps are rated for your truck’s weight and are robust enough for any towing needs.

10. Roadside Assistance Information: Keep a card or a note with your roadside assistance service’s number handy. This can save time and stress in emergencies, allowing you to quickly get the help you need.

By equipping your truck with these essential safety items, you not only protect yourself but also enhance the safety of others on the road. Regularly check and maintain your safety gear to ensure it’s always ready when you need it.

Convenient Storage Solutions for Organizing Your Gear

When it comes to truck ownership, efficient storage solutions are essential for keeping your gear organized and accessible. A well-organized truck can greatly enhance your productivity and ensure you have everything you need when on the road or on a job site.

1. Under-Seat Storage Boxes: Utilizing the space under your truck’s seats is a smart way to maximize storage. Under-seat storage boxes provide a discreet location for tools, personal items, and emergency supplies while keeping your cab clutter-free.

2. Bed Organizers: Invest in bed organizers that help compartmentalize the truck bed, making it easier to store and retrieve equipment. Options include cargo nets, dividers, and bins designed specifically for truck beds to prevent items from sliding around during transit.

3. Tool Boxes: A durable, weather-resistant tool box mounted in the truck bed is not only practical but also increases theft protection for your valuable tools. Look for models that feature secure locks and an easy-access design for convenience.

4. Tailgate Storage Solutions: Tailgate storage systems allow you to utilize the vertical space of your truck. These can include foldable shelves or racks that are attached directly to the tailgate, optimizing the area for quick access to tools or supplies.

5. Overhead Storage Systems: For trucks with a high roofline, consider overhead storage solutions. These can be particularly useful for larger items like ladders or lumber, making it easier to transport without sacrificing bed space.

6. Modular Storage Platforms: Modular systems can be customized to fit your specific needs. These platforms can be adjusted or expanded as required, allowing for flexible organization of tools and gear for a variety of jobs.

7. Cargo Bins: Consider using cargo bins or totes that can be easily transported in and out of your truck. Stackable bins help maintain order, making it easy to find specific items without digging through everything.

8. Seat Covers with Storage Pockets: Upgrading your truck’s seat covers with those that include built-in storage pockets can add extra organization for smaller items like first-aid kits, maps, and electronic devices, keeping them within reach.

9. Magnetic Tool Holders: Install magnetic holders in the truck’s cab or bed to keep tools and metal objects secure and readily accessible. This innovation can reduce the risk of losing small items and keeps them within easy reach.

10. Vehicle-Integrated Storage Systems: Some trucks come with integrated storage features like hidden compartments or cubbies that are designed for specific uses. Familiarize yourself with these features to take full advantage of your truck’s design.

By incorporating these storage solutions into your truck setup, you can enjoy a more organized environment that keeps your gear in order and positions you for success in your endeavors.